Whenever you see a set of stairs, you can be assured its construction was carefully considered. Each set has to meet certain standards before it’s made available for use. But with so many types of stairs, how can you tell which standards yours need to follow?

Stairs can be designed to comply with different regulations depending on their intended environment. Regulatory agencies are the ones who make the distinctions between stairs for the commercial environment versus those for the industrial.

We outline the differences between industrial style stairs and commercial stairs, along with their related safety codes.

Commercial Stairs Built for the General Public

The International Building Code (IBC) regulates any set of stairs used by the public, including any stairway that connects a building to a public space. These regulations must account for the safety of every type of person — including children and the elderly.

According to the IBC, stairways with an occupant load of fewer than 50 people must be at least 36 inches wide. Stairs that are higher than 12 feet tall require an intermediate landing in the middle of the stairway. These landings should be the same width as the stairway and extend at least three feet in length.

For open-sided walking surfaces like stairs and elevated platforms, handrails and guards are mandatory. And IBC-compliant stairs can’t have any gaps between those handrails or guards that could allow a four-inch sphere to pass through. This is to ensure a child’s head cannot pass through any section of the stairway, landing or platform.

The IBC also dictates the rise and tread measurements for each individual step. Rise is the vertical height between any two adjacent steps and can be open (gap between the stairs) or closed ( a solid piece of material between stairs). The tread is the depth of the step itself. IBC-compliant stairs must have a closed riser between four and seven inches, and a tread of at least 11 inches deep.

If your workplace is open to the public, then all stairways should adhere to these IBC guidelines.

Industrial Stairs

Many businesses have private facilities. Stairs in these environments are not for public use. They can include areas like factory floors and manufacturing spaces where only designated employees to work. Therefore, they are not bound by the IBC.

Instead, the Occupational Safety and Health Administration’s (OSHA) Fixed Industrial Stair regulations (1910.24) govern the design, construction and use of both interior and exterior stairs used to access equipment, machinery, tanks, elevated platforms, other floors or pits.

All of ErectaStep’s stair systems (and all our products, for that matter) comply with industrial codes, and there are distinct features we build in to make them OSHA compliant. Learn about Erectastep’s OSHA compliant stairs

These types of stairs are used in industrial settings, so they must be strong. OSHA-compliant stairs are designed to carry a load five times greater than the anticipated load, but never less than a load of 1,000 pounds. Both handrails and guardrails must be capable of withstanding a minimum of 200 pounds of pressure applied from any direction at any point along the rails.

Like the IBC, OSHA dictates specific measurements. OSHA stairs are required to be a minimum of 22 inches wide. Rise and tread measurements are dictated by the angle of the stairway rise. For example, stairs manufactured with a 45-degree stairway rise must have a minimum rise and tread of 8.75 inches each. Risers for OSHA stairs are allowed to be open. Handrails and guardrails are mandatory, but gaps are allowed between rails since children will not be using these types of stairs.

Adhering to these regulations not only keeps you OSHA compliant but also keeps your workers safe and productive. However, if both IBC stairs and OSHA stairs keep employees safe, how do you decide which option is the best for your business?

Less Space, Less Cost

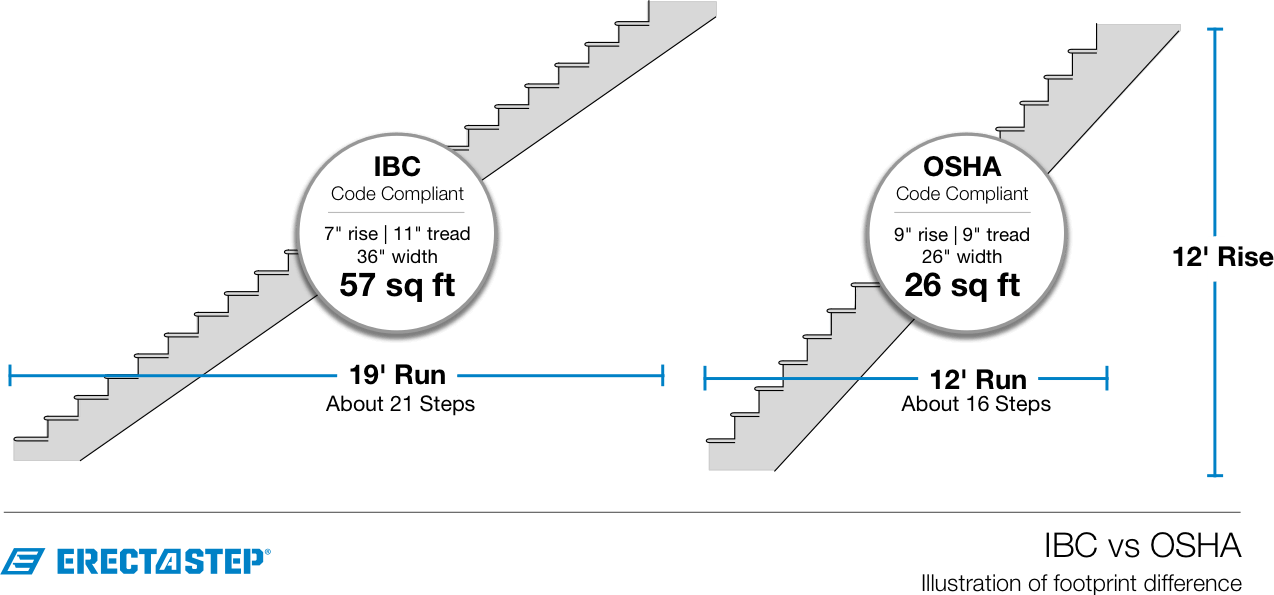

Larger IBC measurements mean these stairs have a bigger footprint than OSHA stairs. As a business, you want the most value out of your facility’s limited space, so it pays to invest in equipment that requires less square footage.

Here’s a side-by-side comparison. In order to access a 12-foot-high platform, an IBC stair would need 21 steps (7-inch rise, 11-inch tread), making the entire horizontal run of the stairs 19.25 feet. Assuming the minimum width of 36 inches, the floor space used by these stairs is 57.75 square feet. That’s a lot of space used for a staircase! (Also keep in mind that any IBC stair higher than 12 feet must also incorporate an intermediate landing area, taking up even more room.)

Here’s a side-by-side comparison. In order to access a 12-foot-high platform, an IBC stair would need 21 steps (7-inch rise, 11-inch tread), making the entire horizontal run of the stairs 19.25 feet. Assuming the minimum width of 36 inches, the floor space used by these stairs is 57.75 square feet. That’s a lot of space used for a staircase! (Also keep in mind that any IBC stair higher than 12 feet must also incorporate an intermediate landing area, taking up even more room.)

On the flip side, take ErectaStep’s stair system, which is fully compliant with OSHA’s codes. To access that same 12-foot platform with these stairs would require just 16 steps (9-inch rise, 9-inch tread), meaning the horizontal run would only be 12 feet long. Factoring in ErectaStep’s 26-inch width gives you a solution that uses 26 square feet of floor space — which is less than half the space required by an IBC stair to access the same platform.

(Plus, ErectaStep’s stairs go above and beyond with a wider width and longer tread than the OSHA minimum – read more about our product specs here.)

Another key difference is cost. It takes less material to construct OSHA stairs since IBC stairs require closed risers and no gaps larger than four inches between handrails and guards. As long as the public does not have access to your equipment, an OSHA-compliant solution can save you thousands.

ErectaStep’s OSHA-compliant solutions require less space, cost less and are completely customizable. The five components can be assembled in infinite ways, allowing you the flexibility to select a safety solution that will work best in your facility. We can even customize individual measurements, like rise and tread, with our PerfectaStep solutions, giving you the perfect configuration for your job site.

Regardless of the stair type, you’re looking for, be sure you speak with your vendor early about code compliance and what’s needed for your work environment.

OSHA |

IBC |

|

| Risers & Tread | 8″ open riser a 9.5″ tread |

7″ closed riser, max 4″ open gap. 11″ tread |

| Stair Width | A minimum 22″ wide stair | A minimum 44″ wide in most cases (36″ wide areas served by less than 50 people) |

| Railings & Guardrail | OSHA requires railings on open sides of stairwells and a handrail on at least on the side, preferably the right side descending at 42″ high. | IBC Stairs require guardrails of 42″ high and handrails of 34″ high on both sides of the stairwell. |

| Balusters (vertical members in handrails) |

Space between balusters should be no more than 19″ (48 cm) apart | Space between balusters should be no more than 4″ apart |

| Landings | Both OSHA and IBC require landings at the top and bottom of the stairs, although IBC landings are larger, typically 4′ square. | IBC also requires an intermediate landing on stairwells for stairwells over 12′ high, as well as handrail extensions at the bottom landing. |

*This chart is for general reference. Regulations do change.

Regulation Reference:

Risers & Tread – OSHA stair tread requirements 90 | IBC stair width 50 | OSHA stair maximum riser height 70 | OSHA stair riser height 70

Stair Width – OSHA stair tread requirements 90

Railings and Guardrails – OSHA handrail requirements 390 | IBC handrail 320

Balusters – OSHA 1910.29(b)(2)(iii)

Credit: https://www.erectastep.com/safety-codes-whats-the-difference-between-ibc-and-osha-stairs/